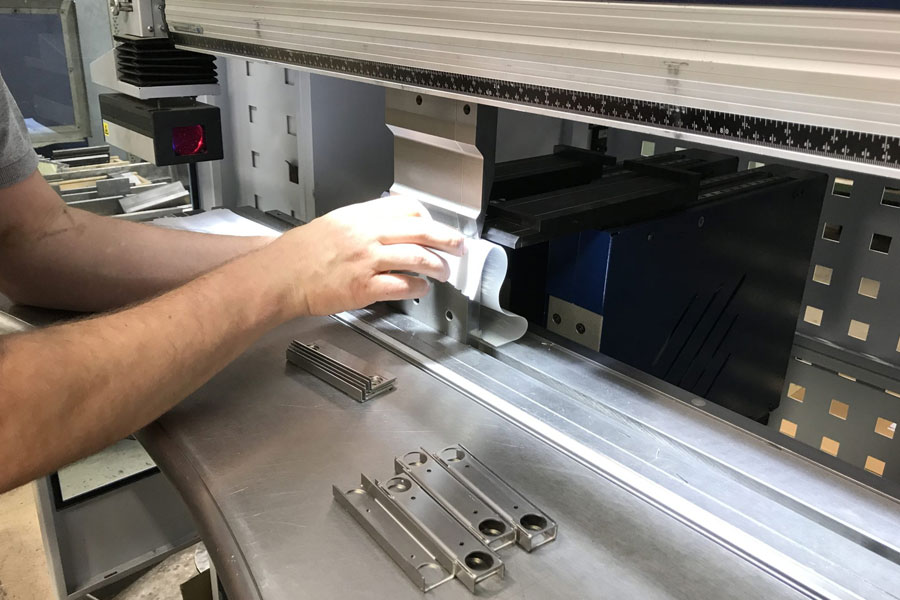

CNC bending is a precision metal forming process that uses computer-controlled press brakes to bend sheet metal and tubes into desired shapes. This technology ensures high accuracy, repeatability, and efficiency, making it ideal for industries such as automotive, aerospace, construction, and fabrication. CNC bending provides smooth, consistent bends while minimizing material waste.

Key Features

- High Precision & Accuracy – Consistent bending with tight tolerances.

- Versatile Material Handling – Works with steel, aluminum, stainless steel, and more.

- Automated & Computer-Controlled – Ensures repeatability and efficiency.

- Complex & Custom Bends – Accommodates intricate designs and shapes.

- Minimal Material Waste – Optimized bending reduces scrap.

- Fast & Cost-Effective – Speeds up production while lowering costs.

- Non-Damaging Process – Prevents cracks and deformities.

- High Load Capacity – Suitable for thick and heavy-duty materials.

- Scalable for Mass Production – Efficient for both small and large-scale manufacturing.

- Wide Industrial Applications – Used in construction, automotive, aerospace, and more.